Precision Plastic Injection Molding

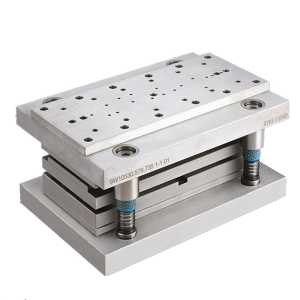

Although the structure of the mold may vary due to the variety and performance of plastics, the shape and structure of plastic products, and the type of injection machine, the basic structure is the same. The mold is mainly composed of pouring system, temperature regulation system, forming parts and structural parts. Among them, the gating system and the molding parts are the parts that are in direct contact with the plastic, and change with the plastic and the product. They are the most complex and changeable parts in the mold, and require the highest processing finish and precision.

| Product name: | Prototype |

| The company's strengths: | 1,Efficient team with many years' experience |

| 2,Delivery in time | |

| 3,Excellent equipment | |

| 4,High quality and competitive price | |

| Material: | ABS,POM,PP, PU,PC,PA66,PMMA,PVC,PVE, Aluminum,Steel |

| Color | Any color, according to customers' requirements. |

| Surfaces treatment: | light color,dumb color,rubber oil,pearlescent color,Silk-printing, anodize,chrome plating |

| File Formats: | Pro/engineer,Solidworks,UG,Auto cad |

| Lead time | 25-50days based on the different products |

| Services | 1,industrial design |

| 2,Brass/Aluminum parts machining | |

| 3,Reverse engineering | |

| 4,Injection molding | |

| 5,Rapid silicone mould and vacuum casting | |

| 6,CNC prototype manufacturing | |

| Business Fields | 1. Project Development (ODM&OEM project) for Industrial Design, ME and Hardware Design, Tooling process and Mass production. |

| 2. Magnesium- Alloy & Aluminum-Alloy part manufacturing | |

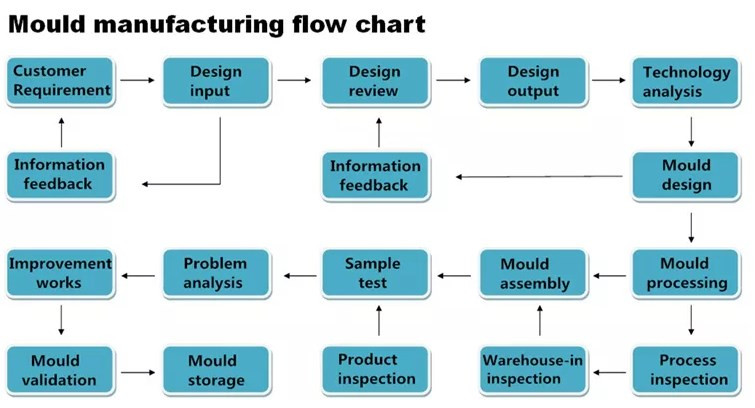

| 3. Tooling process (Plastic mould, Stamp-Die, Die-Casting and Sand Casting) | |

| 4. Metal machining part manufacturing | |

| 5. Rapid Prototyping | |

| 6. Low volume production by CNC, RTV, and Fast-mould etc. |