Story About Soot

Founded in Aug 1999,Zhejiang Soot Electric Co., Ltd is one of the largest manufacture bases of electrical stamping parts in China

With its output value reached RMB200 million in 2021.Our plant area covers 15mu and the building area reaches 18,700 square meters.

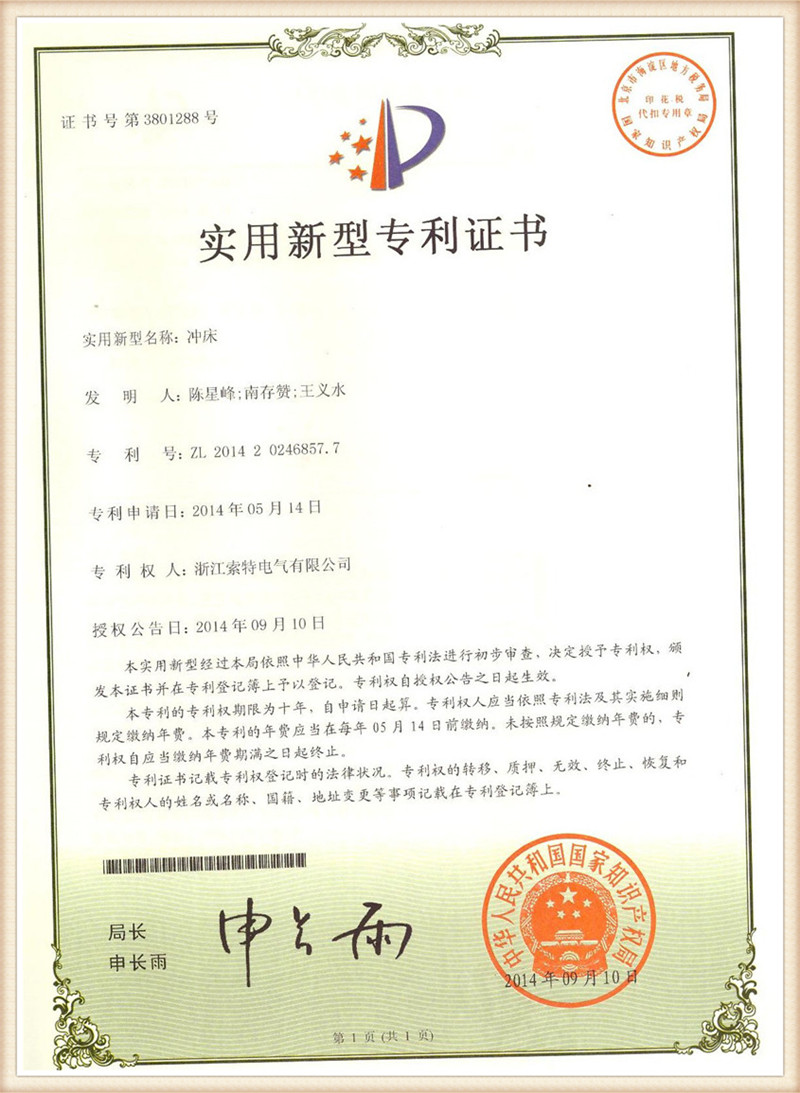

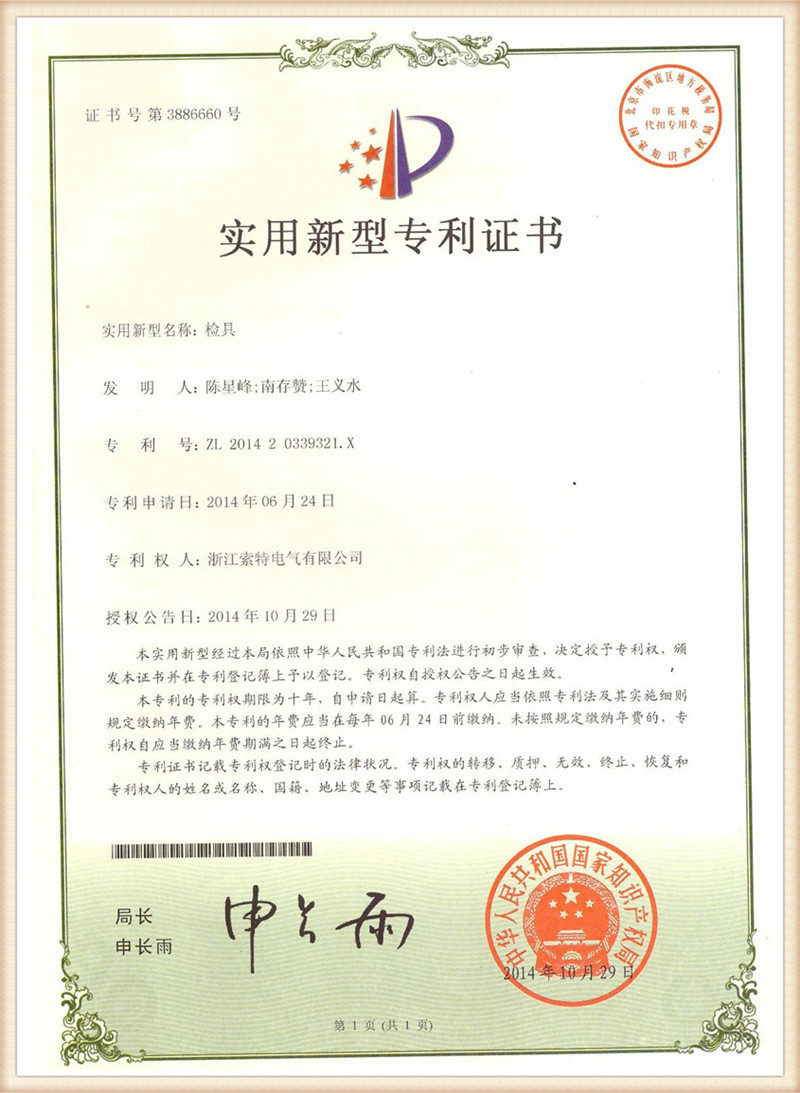

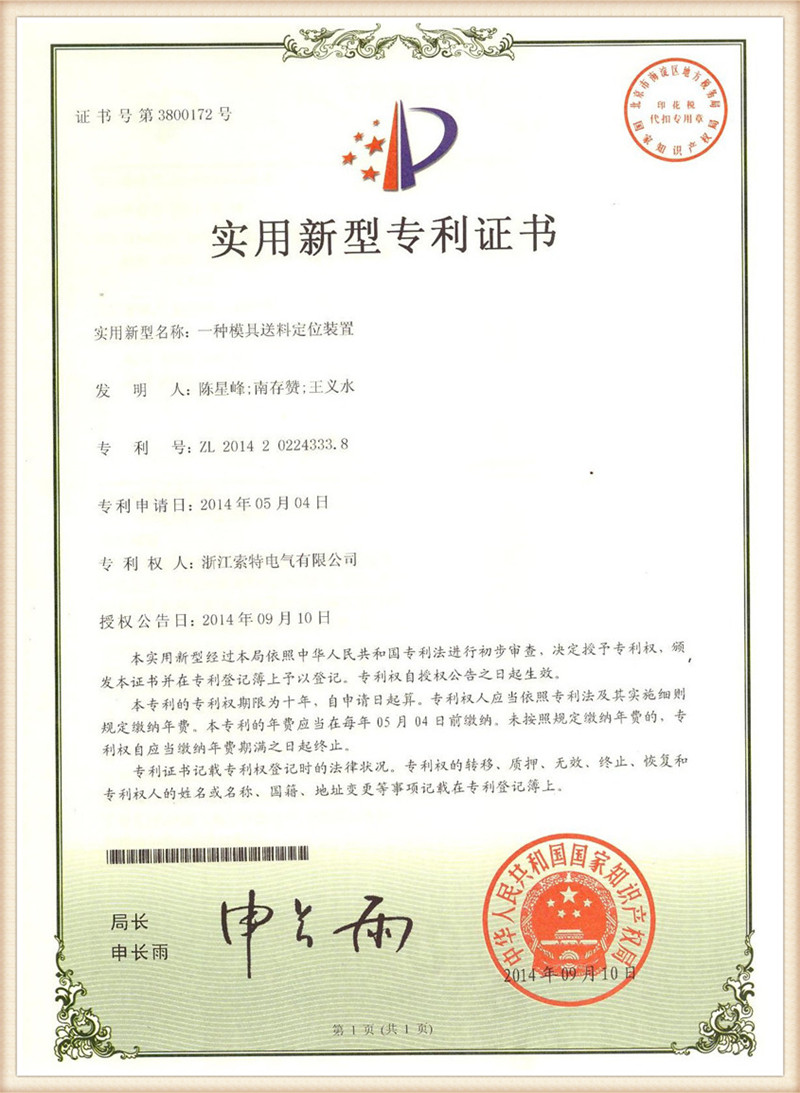

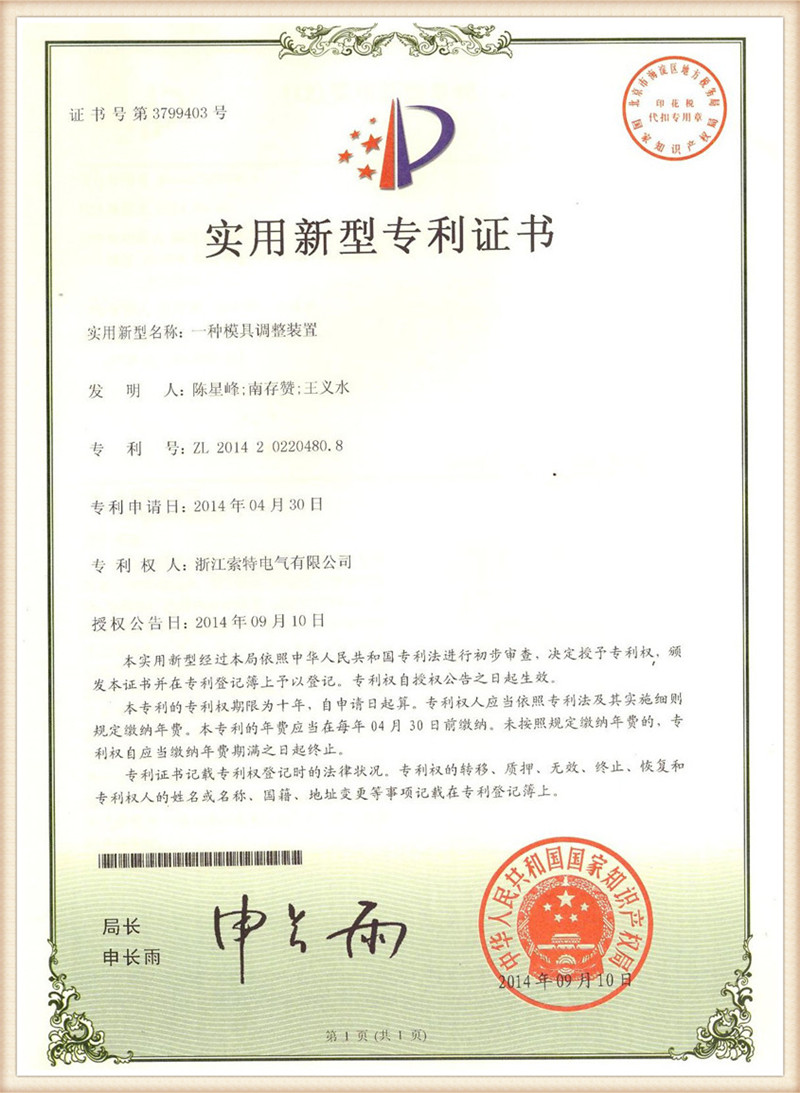

Soot has more than 200 employees, includng more than 30 engineers and technicians. In addition, we have professional and automatic hardware facilities which integrate R&D, design, manufacture and service of moulds. As one of the first enterprises that passed the IS09001 International Quality Management Certification, we strive to provide high quality and reliable products by constantly exploring innovation.

TECHNICAL R & D

SOOT R&D Center is established based on the huge market potential of stamping products in the field of electrical appliance manufacturing and great attention to the product quality’s high standards and high demands as well as the diversity of product development. It aims to make the most rapid response to the technical demands and improvement of the stamping products. So far, we have the intellect research and development system of CAD, CAM and CAE integrating design, manufacturing as well as analysis. In the meanwhile, we actively carry out international technical exchanges with peers and provide excellent product development and manufacturing solutions for customers.

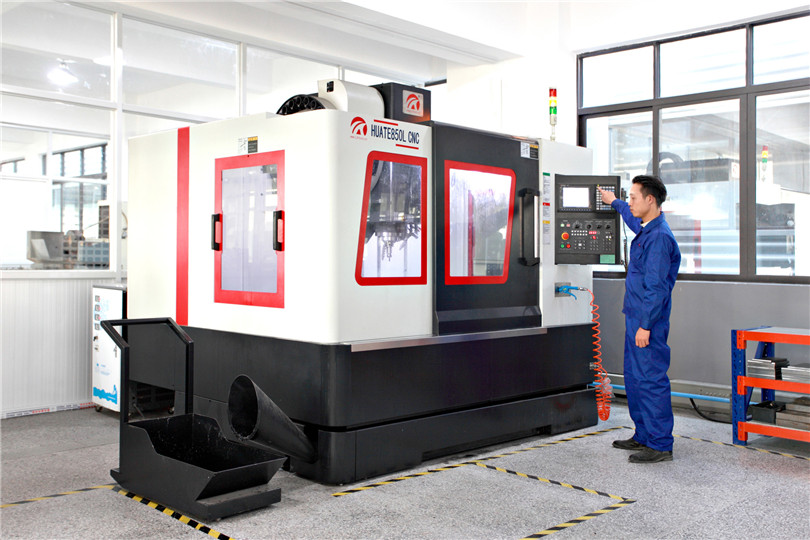

MOULD CENTER

It provides customers with high-speed and precise stamping molds so that the mold research and manufacturing ability of the company can take the leading position in domestic industry.

SOOT Mold Center has more than 30 technical teams of experienced and skilled mold design, process planning and processing assembly.

Furthermore, it has CNC processing workshop, cutting workshop of slow wire and middle speed wire, the workshop of precise finish and the workshop of mold assembling.

ERP mold integrated management system and design technology of CAD, CAM and CAE are used for mold design, manufacturing and testing.

STAMPING CENTER

Standardized Stamping Center has a total of 50 high-speed precision presses of 10-200 tons, with an annual production capacity of 30 trillion pieces. High-precision and advanced production equipment is the fundamental guarantee for high quality. The hardware facilities make the modern enterprise even more powerful, so as to continuously produce products with high technology content and first-class quality. Souter has introduced first-class production equipment lines from home and abroad, and introduced intelligent manufacturing systems to achieve digital all-round management. Improve the quality monitoring system in an all-round way, so that SOT stampings can seize the market opportunity and create a superior brand.

COMPONENTS ASSEMBLY SHOP

There are more than 100 staffs and 3 regular routine assembly lines in t h e Component Assembling Workshop. 16 kinds of products can be assembled at the same time, mainly including various low-voltage electrical components.

LOGISTICS CENTRE

SOOT establishes a system based on digital management to create a cloud data that is shared with customers in real time.

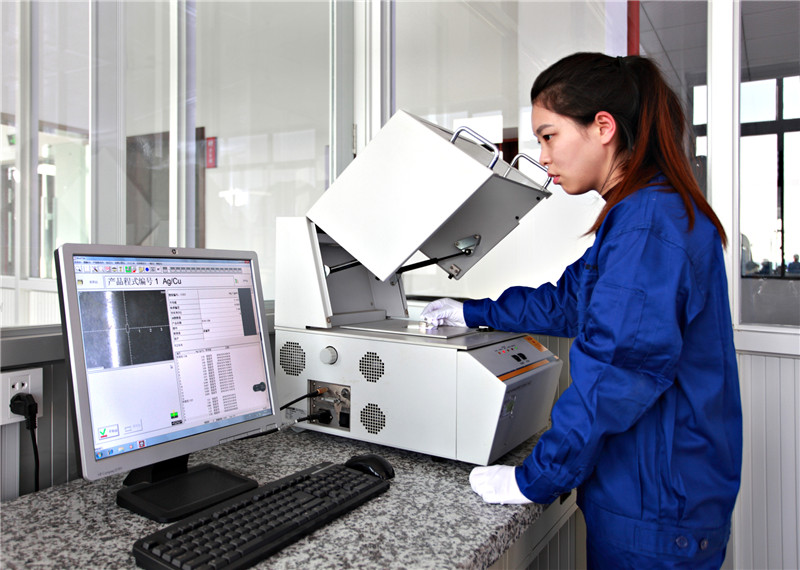

QUALITY ASSURANCE

In order to comply with the company's development needs, to ensure product performance, reliable quality, customer satisfaction, the quality department is equipped with Germany's Fischer coating thickness gauge FISCHER, the United States OGP image measuring instrument and other advanced testing equipment, and established a sound quality. The management platform forms an all-round quality control system with quality as the center such as IQC, measurement and CQE, and implements effective monitoring of the whole process of product realization in strict accordance with the requirements of ISO9001 quality system and IATF16949 quality management system certification.