OEM Custom Stamping Die Parts Factory - Precision progressive stamping die – Soot Electric

OEM Custom Stamping Die Parts Factory - Precision progressive stamping die – Soot Electric Detail:

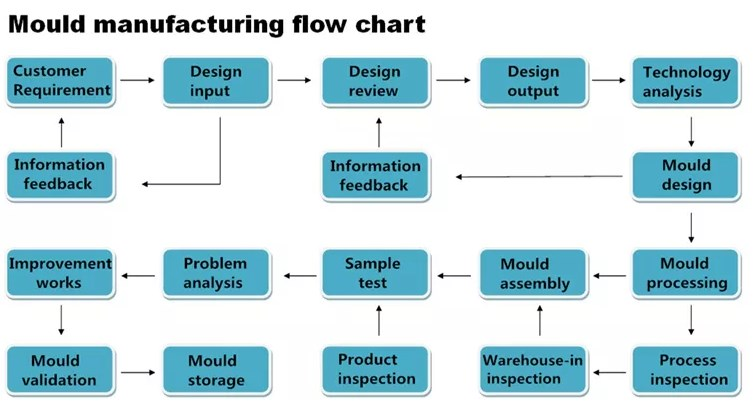

Usually, stamping refers to a single operation in which a part of a part is formed on one machine and then transferred to another machine or group of machines. This process requires multiple molds to be installed on several devices. Finishing and molding are separate operations performed after parts have passed through various machines. Continuous stamping eliminates the need for multiple machines to perform multiple functions and process workpieces in a set of operations. A rolled metal strip is expanded into a single molding machine with multiple stations, which perform their respective functions. Each station adds previously completed work, resulting in a completed part.

Progressive stamping simplifies the production of complex and complex parts, shortens the production time, and improves efficiency. Since the part is still connected to the metal roller, the motion must be accurately aligned. The first station separates the manufactured parts from the rest of the metal. Continuous stamping dies are ideal for long-distance stamping because they have a longer service life and do not cause any damage due to the stamping process. Like several stamping processes, progressive stamping is repeatable. Each station performs a different cutting, bending, or stamping to gradually achieve the desired end shape and design. The speed of progressive die casting is fast, and the waste product is less.

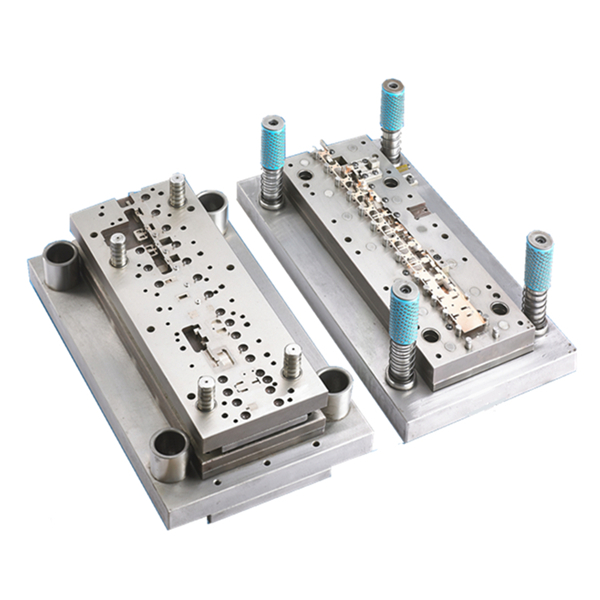

| Product Name | Precision stamping die |

| Material | SKD11, SKD 61, Cr12 MOV ect |

| Design Software | Auto CAD, PRO/E, Solid works, UG(NX), Cimatron |

| Standard | ISO9001-2015 |

| Mould type | Punching progressive mould |

| Surface treament | Zinc plated, nickel plated, tin plated, brass plated, silver plated, gold plated ect. |

| Service time | 5,000,000-10,000,000 |

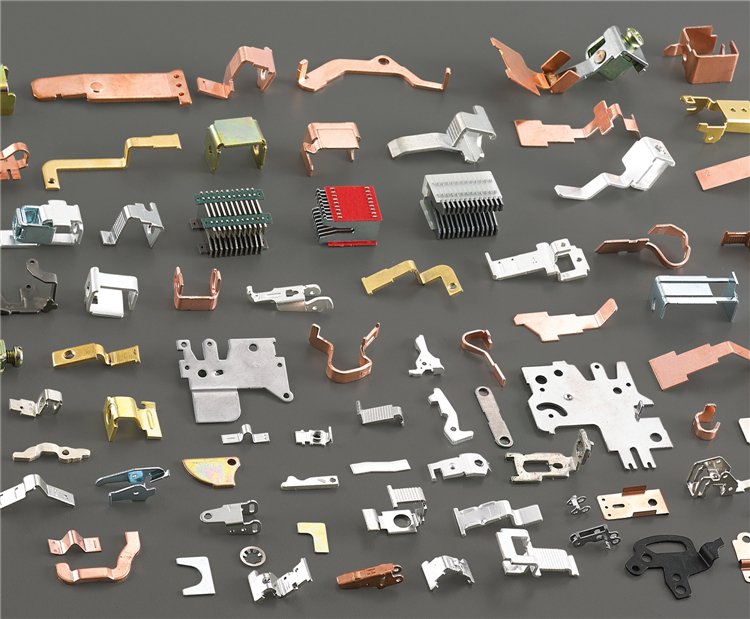

| Used | circuit breaker,wall switch and socket,outlet,Ac contactor and auto ect |

| Packing | wooden case for Die/mold, or as customer’s requirements |

| Product tolerance | GB-T15055 or ISO2678 |

Product detail pictures:

Related Product Guide:

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for OEM Custom Stamping Die Parts Factory - Precision progressive stamping die – Soot Electric, The product will supply to all over the world, such as: Sri Lanka, Lithuania, Egypt, Our company upholds the spirit of innovation, harmony, team work and sharing, trails, pragmatic progress. Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.